RESOURCES

Whether you’re looking for case studies, the latest news, or a specific product brochure – the AMS Resource Center can help. Use the drop down menus below to find what you’re looking for.

Select the Contaminants

Select the Markets

- All Markets

- Agriculture

- Coal-Fired Power Stations

- Corrosion Monitoring & Control

- Drinking Water

- Environmental Monitoring

- Food & Beverage

- General Chemical Industry

- Oil Refining

- Plating

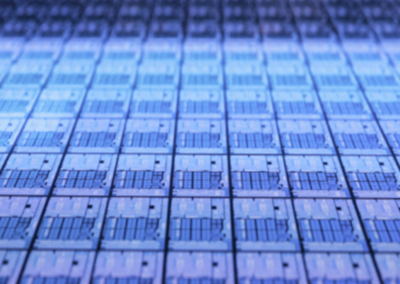

- Semiconductor & Electronics

- Solar Energy

- Wastewater

- Landfill Leachate

- Oil & Gas

- Pharmaceutical

- Petrochemical

- Mining, Fracking & Smelters

- Mining

- Fracking & Smelters

Select the Resource Types

City of Santa Cruz Adopts Online THM Analyzer for Disinfection By-Product Management

Online THM Analyzer Integral to City of Benicia’s Stage 2 DBPR Compliance Strategy

TRUMPF Optimizes Ion Exchange System With Reliable and Continuous Data From Real-Time Arsenic Analyzer

AMS Talks: The Value of Data to Aigües de Barcelona

AMS Talks: Transformative Innovation for Affordable Compliance

Addressing PFAS Challenges: Insights from AMS at WEFTEC 2024

AMS Advanced Monitoring Solutions

AMS Talks: Brunswick & Topsham Water District THM Optimization

AMS Talks: City of Alamosa Evaluates SafeGuard™ H2O Arsenic Removal Technology

AMS Talks: Managing Heavy Metal Exceedances

AMS Talks: The Value of Data to Aeration and THM Removal